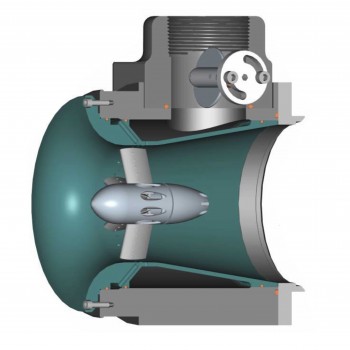

Vm 350 Mixing Venturi

Overview

The VM-350 can be used with any single or dual bank natural gas engine. It generally directly replaces the mechanical carburetor and offers improved air and fuel mixing. By providing a multitude of fuel inlet vanes and passages evenly dispersed throughout the low-pressure region of the venturi, the fuel is more evenly distributed and providing a more homogenous mixture to the engine.The VM-350 includes a carefully designed venturi designed specifically to maintain a constant fuel mixture and any load by drawing just the proper amount of fuel for the specific amount of air that is being drawn into the engine.

This will ensure that the ratio of fuel to air is constant and it will make the work of the air fuel controller much easier. Mechanical carburetors are often designed to run richer as the load increases. The VM-350 will flatten out the fuel profile so that at any load the mix will still be about the same.

If the engine is to be run in a lean burn mode, the improved mixing will extend the lean limit allowing the engine to be run leaner than it normally can with a traditional carburetor.

We recommend using the Continental Controls ECV 5 in conjunction with the VM-350. This valve can precisely control fuel pressure which is ideal for fuel control along with a venture.

Warning: A mechanical Carburetor normally provides for one last gas shutoff. With the diaphragm and the traditional carburetor removed, this final shut off has been eliminated. The user will be responsible for insuring that the control system has the ability to reliably and safely shut off all of the fuel to the engine.

Specification

- Replaces Mechanical Carburetor and Improves Air / Fuel Mixing

- No Moving Parts Reduces Maintenance

- Consistent Fuel Manifold Pressure at all Loads Enhances Air Fuel Ratio Control

- Dual Bank Engines can be Easily Balanced

- Less Pressure Drop Than with Traditional Carburetor